Home > Products

PRODUCTS

- Printing chemicals

- Flat offset offset fountain solution

- Newspaper printing moistening solution -- cold fixing

- Commercial rotary printing fountain solution - thermosetting

- Fountain solution auxiliary products

- Water-borne light oil

- Light oil

- Dumb oil

- Special light oil

- Printing powder

- Oily spraying

- Hydrophilic and oily spraying

- Silicone lubricating emulsion

- Thermosetting rotary printing of silicon oil

- Printed chemicals

- Printing plate acid cleaning liquid

- Basic cleaning liquid

- Plate protector

- Baked version of glue

- Developer solution

- Printing cleaner

- Rubber blanket & ink roll cleaner

- Environmental friendly water-based cleaning agent

- Ink roll maintenance

- Others

-

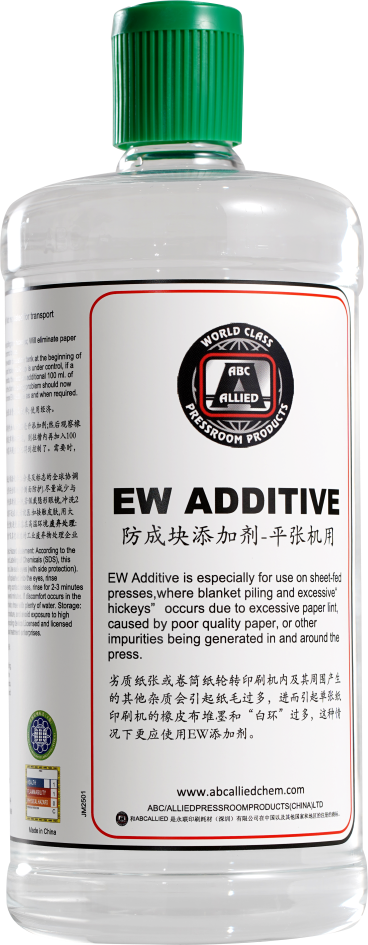

Appearance: liquid, color: transparent

Odor: No special odor. Solubility: Completely soluble in water.

Boiling Point: 100 Relative Density: 20 1.06

PH value: 4.5 flash point: none

- Application:

Low-quality paper or other magazines produced in and around the drum rotary machine can cause excessive paper wool, which in turn leads to excessive ink stacking and "white ring" on the rubber cloth of sheet-fed presses. In this case, EW additives should be used. Before starting the printing work, a small amount of EW additive is added directly to the water tank of the printing press to prevent ink piling or white ring formation of rubber cloth. In this way, the printer operator can concentrate on printing without having to stop the printer frequently to clean the rubber cloth.

Features:

1. Eliminate and control rubber cloth inking and white ring;

2. Avoid waste of paper;

3. Improving efficiency

4. Use economy.

Usage: At the beginning of each shift, 200 ml EW additive is added to the water circulation tank; then, whether the ink pile-up and white ring pile-up of rubber cloth are alleviated or not, if there is still a slight rubber cloth pile-up or white ring problem, 100 ml additive is added to the tank. At this time, the rubber cloth ink pile-up problem of the whole shift should be controlled. More EW additives can be added when needed.

Packaging: 1 liter/bottle, 12 bottles/cases

Storage: A cool, dry and ventilated warehouse with storage temperatures ranging from 0 C to 40 C. A small amount of stratification is a normal phenomenon, shake well before use.

Shelf life: the original package is not opened, keep 0 C to 40 C, avoid direct sunlight, the shelf life is 24 months.