- 2019-05-14

- Rapid and efficient treatment of printing water? You need a moisturizer!

- The role of embossing solution in printing

ABCALLIED Yonglian

Rapid and efficient treatment of printing water? You need a moisturizer!

In the printing process, the embossing solution is usually used to ensure that no ink appears in the non-printing area of offset plate. The embossing solution has the following seven main functions:

Make ink and plate separated by a layer of water film;

Maintaining the hydrophilic nature of the plate

At the beginning of the printing task, the ink is quickly separated from the plate.

Accelerate the extension of water on the printing plate surface

Facilitate the smooth flow of the embossing roll horizontally

Lubrication of plate drum and film drum

The emulsification of ink and water was controlled.

The embossing solution generally consists of five main parts:

A. Water: This component accounts for the vast majority of the embellishing solution.

B, acid: acid can reduce the PH value, maintain the sensitivity of printing area to ink, but also maintain the sensitivity of the background area to water;

C, wetting agent: or surfactant, it can reduce the surface tension of water, so that water can maintain the wetting characteristics of the non-print area of the printing plate. If the amount of water is reduced to the necessary amount to keep the printing plate clean, the amount of ink needed for printing should also be reduced. Isopropanol is one of the most popular and widely used wetting agents.

D. Printing regulator/additive: It can reduce the corrosion of acid to aluminium plate. This can not only prolong the printing plate life, but also improve the overall printing quality. Most embossing solutions contain trans-antifungal reagents and buffer compounds to maintain the acidity of the solution. Anti-accumulation solvents prevent the solution from accumulating. The presence of silicon can reduce the adhesion of film and reduce the adhesion caused by acid dipping of paper.

E. Arabic resin: Arabic resin is often added to the embossing solution at present. Its function is to glue it to the non-printing area of the printing plate so that the part will not be dyed by ink. In addition, in the process of stopping printing, the Arabic resin can also prevent the printing plate from being damaged by humidity and chemicals. At present, some manufacturers use alternatives to gum arabic. However, Arabic resin is still the most effective material in keeping the non-printing area clean.

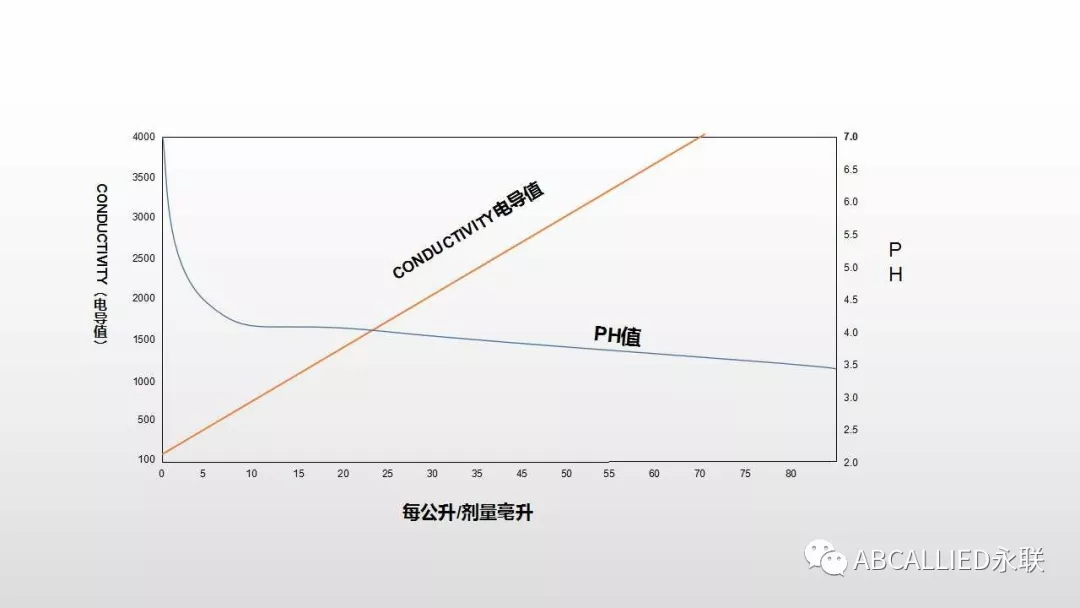

No matter how the composition changes, PH value and conductivity value are still the conditions that must be taken into account in the embossing solution.

PH value and conductivity are two very important properties of embossing solution. What is PH value? As early as in Roman times, it was defined as the chemical formula of hydrogen ion, so it was expressed by the lowercase letter "p" and the capital letter "H". PH value is a quantity used to express the acidity and alkalinity of substances. Its control is very important to ensure high quality printing, and no problems in the printing process. The acid in the embossing solution strengthens the function of the resin and protects the resin from being damaged. For example, citric acid, when diluted sufficiently, can be combined with Arab resin to release citric acid molecules from the resin. These citric acid molecules can be combined with metal oxides such as alumina on the printing plate, which makes the surface of the non-printing area of the printing plate hydrophilic as we want. But the above hydrophilicity can be easily destroyed, but every time the embossing solution is used again, that is, every turn of the offset roller, this effect will be strengthened. In the process of printing, the stability of PH value should be ensured as far as possible. When there are contaminants in the embossing solution, such as calcium carbonate, the PH value of the solution will change. A certain amount of buffer reagent should be added to ensure the stability of the PH value of the embossing solution in the printing process.

The range of PH value is between 0 and 14. When the value is 7.0, it means that the solution is in the medium state. The solution with PH value higher than 7 is alkaline, and the higher the value, the stronger the alkalinity. Solutions with PH value less than 7.0 are acidic, and the change of PH value indicates that the acidity and alkalinity of the solution with PH value less than 7.0 are 10 times that of the solution with PH value of 5.0, for example, 10 times that of the solution with PH value of 6.0. In order to accurately determine the pH value of the solution, a precise electronic measuring instrument should be used. PH value test paper can also be used, but its accuracy is generally not high. Conductivity values indicate the performance of substances in transporting or transporting charges. In water or other solutions, the conductivity value reflects the amount of ions carried by minerals or other compounds in water. Basically, the higher the ion concentration in the solution, the stronger the conductivity. Water generally contains fewer ions, so its conductivity readings are correspondingly low. On the other hand, hydrochloric acid, with high ionic strength, is a very good conductive liquid, so it has high conductivity. Ethanol itself has no ability to transmit charges, so its conductivity value is zero, and glycerol is similar to ethanol, its conductivity value is close to zero. Therefore, when ethanol or glycerol is added to the solution, the solution is diluted and the conductivity decreases accordingly. What does that mean? This shows that the conductivity value is a characterization of the impurity content in the embossing solution. When the impurity enters the embossing solution, the conductivity value will increase.

Conductivity values indicate the performance of substances in transporting or transporting charges. In water or other solutions, the conductivity value reflects the amount of ions carried by minerals or other compounds in water. Basically, the higher the ion concentration in the solution, the stronger the conductivity. Water generally contains fewer ions, so its conductivity readings are correspondingly low. On the other hand, hydrochloric acid, with high ionic strength, is a very good conductive liquid, so it has high conductivity. Ethanol itself has no ability to transmit charges, so its conductivity value is zero, and glycerol is similar to ethanol, its conductivity value is close to zero. Therefore, when ethanol or glycerol is added to the solution, the solution is diluted and the conductivity decreases accordingly. What does that mean? This shows that the conductivity value is a characterization of the impurity content in the embossing solution. When the impurity enters the embossing solution, the conductivity value will increase.